Grittal

GRITTAL is the economic alternative to mineral grit abrasives and fulfills all requirements concerning blasting performance and a corrosion-free surface finish.

GRITTAL offers clear economic and environmental advantages.

The extremely high durability of this rust-free stainless steel grit reduces the amount of abrasive consumption by a factor of 30 – 100 and thereby also minimizes the amount of waste that is generated.

The durability of GRITTAL results in a consistent work mix, constant roughness values and guarantees quality adhesion for subsequent coatings.

GRITTAL’s dust-free characteristic allows for excellent vision while blasting and helps to better control the blast process.

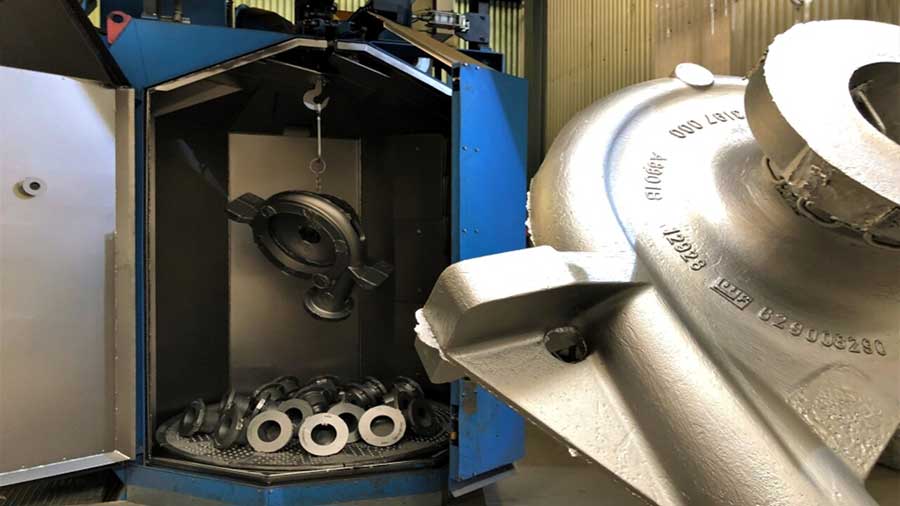

GRITTAL is successfully used in blast rooms and blast cabinets as well as in centrifugal wheel blast machines.

Chemical composition: C 1.9-2.1%, Cr 30 - 33 %, Si 0.7-1.0%

Bulk density: 250lbs./ft3

GRITTAL GH (patented fabrication)

Hardness: ~ 64 HRC (~ 800 HV)

Microstructure: Martensitic with Chromium Carbides

GRITTAL GM

Hardness: ~ 58 HRC (~ 660 HV)

Microstructure: D-Ferrite with Chromium Carbides

Main fields of application:

- Blast cleaning, deburring, surface preparation prior to coating, stone cutting in gang saws

- All types of aluminium castings and forgings

- Zinc pressure die castings

- Non-ferrous metals and special alloys

- Stainless steel castings and forgings

- Machinery and welded structures in stainless steel

- Hot dip galvanized material

- Concrete and natural stones

GRITTAL offers the following advantages:

- Great durability

- Short blasting times

- Bright appearance

- Rust-free surfaces

- Can be used in centrifugal wheel machines as well as air blast systems

- Low waste disposal costs

- Dust-free blasting process

Blasting of metals...

- For efficient deburring

- For bright appearance

- For surface preparation prior to coating

- Effective descaling

Stone blasting…

- For smooth and textured surfaces

- For non-slip surfaces

- For dramatic appearance

Cutting…

- For precise cuts

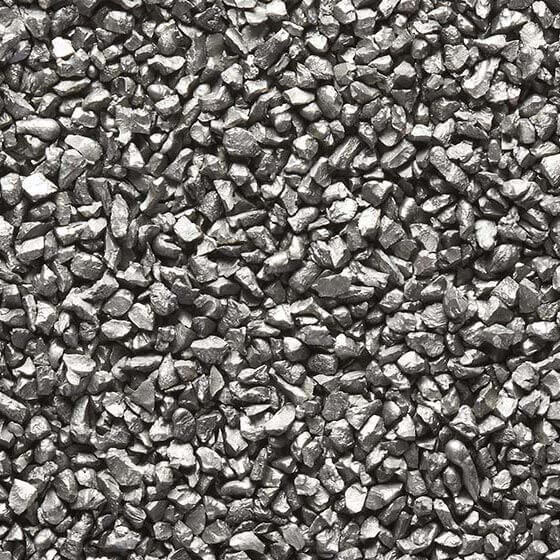

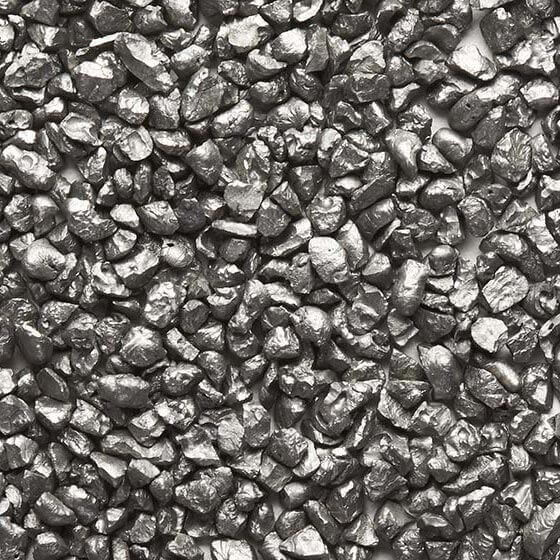

Grain Sizes

High Chromium Alloyed Stainless Grit

Images shown for visual comparison only - NOT ACTUAL SIZE

G-10

G-20

G-30

G-40

G-50

G-60

G-100

G-150

G-200

G-300

Packaging

- 55 lb Bags

- 1100 lb Pallet

- 1760 lb Drums

- Other packaging available upon request

Subject to change without notice.

All specifications are only a general description of the products.